Landfill gas-to-energy conversion units in California convert captured methane into valuable resources, including electricity through generators, renewable natural gas (RNG) for vehicles by injecting it into pipelines, and even liquefied natural gas (LNG) as a high-Btu fuel. These technologies, found at sites like the Frank R. Bowerman Landfill and the Altamont Landfill, use processes like engine combustion or specialised high-tech plants to transform biogas into usable energy and products.

Key Takeaways

- California's landfill gas-to-energy projects are transforming harmful methane emissions into renewable natural gas, with the Keller Canyon facility capable of producing 1 billion cubic feet of RNG annually

- Converting landfill gas to energy reduces greenhouse gas emissions by capturing methane that is 28 times more potent than CO2, with the Keller Canyon project alone reducing carbon emissions by 62,000 metric tons yearly

- The partnership between Republic Services and Ameresco at Keller Canyon represents the first RNG interconnection from a landfill gas project for PG&E's pipeline system

- California's LFG-to-energy transformation supports the state's ambitious climate goals of 60% renewable energy by 2030 and carbon neutrality by 2045

- Beyond environmental benefits, these projects create green sector jobs and generate revenue from previously wasted resources while reducing reliance on fossil fuels

Every day across California, an invisible transformation is taking place at landfill sites. What was once considered merely waste is now becoming a valuable renewable energy resource. The secret lies beneath the surface, where decomposing organic matter produces a potent greenhouse gas that's being captured and repurposed rather than released into the atmosphere.

![]()

“Landfill Gas to Energy – Hoodwinked in …” from climatefalsesolutions.org and used with no modifications.

From Waste to Watts: How California's Landfills Are Becoming Power Plants

California is pioneering an environmental revolution by converting landfill gas (LFG) into renewable natural gas (RNG). This transformation isn't just reducing harmful emissions—it's creating a sustainable energy source that can power homes, businesses, and even vehicles. The innovative approach turns what was once a climate liability into a renewable asset, demonstrating how waste management and clean energy production can work in harmony to address climate challenges.

The Hidden Energy Source Beneath Our Trash

Beneath mountains of household waste lies an untapped energy source with remarkable potential. As organic materials decompose in the oxygen-deprived environment of landfills, they naturally produce a gas mixture primarily composed of methane and carbon dioxide. Until recently, this gas was typically vented or flared, releasing greenhouse gases into the atmosphere or simply burning them off. Today, advanced collection systems capture this valuable resource before it escapes, transforming an environmental liability into renewable energy.

“County landfill could produce renewable …” from www.loudountimes.com and used with no modifications.

Why Landfill Gas Is a Climate Threat When Left Uncaptured

When landfill gas escapes into the atmosphere, it contributes significantly to climate change. Uncaptured LFG releases methane directly into the air where it traps heat in the atmosphere. Without proper management systems, landfills become major sources of greenhouse gas emissions that accelerate global warming. Many older landfills across America still allow these gases to escape, creating an urgent opportunity for environmental improvement through capture systems. The environmental threat posed by uncaptured landfill gas extends beyond climate impacts to include air quality concerns for surrounding communities.

- Uncaptured landfill gas contains volatile organic compounds (VOCs) that contribute to smog formation

- Methane from landfills accounts for approximately 16% of all methane emissions in the United States

- Without capture systems, a single large landfill can emit greenhouse gases equivalent to hundreds of thousands of vehicles

- Escaped LFG can travel through soil, potentially creating safety hazards in nearby structures

- Proper LFG management eliminates unpleasant odors that affect communities surrounding landfill sites

The Methane Opportunity: 28x More Potent Than CO2

Methane deserves special attention in climate discussions because of its extraordinary warming potential. This greenhouse gas is approximately 28 times more potent than carbon dioxide over a 100-year period, making its capture and conversion particularly valuable for climate mitigation. When we redirect methane from landfills into energy production, we're not only preventing a potent greenhouse gas from entering the atmosphere but also displacing fossil fuels that would otherwise be burned. This double climate benefit makes landfill gas projects among the most effective emission reduction strategies available today.

“Reducing Greenhouse Gas Emissions …” from www.tetratech.com and used with no modifications.

California's Landfill Challenges and Climate Goals

California faces unique waste management challenges due to its large population and limited landfill space. The state generates approximately 76 million tons of waste annually, with about 42 million tons ending up in landfills. This reality, combined with the state's ambitious climate goals of achieving 60% renewable energy by 2030 and carbon neutrality by 2045, has created powerful incentives for landfill gas recovery. LFG-to-energy projects directly support these goals by reducing methane emissions while simultaneously increasing the proportion of renewable energy in the state's portfolio. For California, these projects represent a critical component of the comprehensive climate strategy needed to meet its nation-leading environmental targets.

Inside the LFG-to-Energy Conversion Process

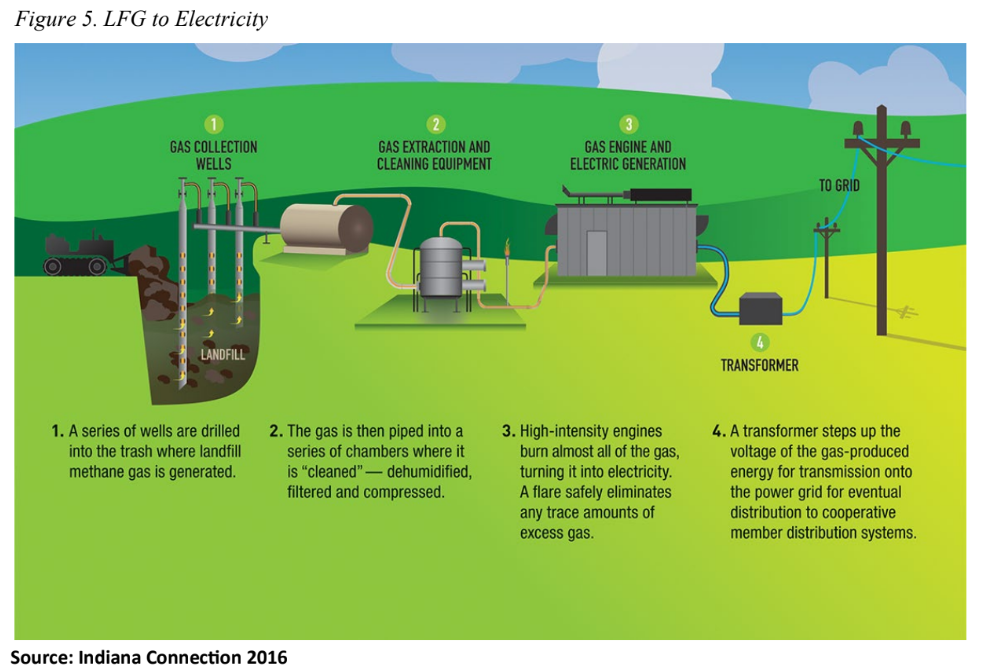

Converting landfill gas into usable energy involves sophisticated engineering systems that capture, clean, and process the gas. The journey from waste to watts begins beneath the surface of the landfill where decomposition creates a steady supply of methane-rich gas. This natural process, when properly harnessed, provides a continuous renewable energy source that can operate for decades during and after a landfill's active life. For more detailed data on these projects, visit the EPA's landfill gas energy project data page.

How Landfill Gas Is Collected and Processed

The collection process starts with a network of strategically placed vertical wells drilled into the landfill mass. These wells, typically made of perforated PVC pipe, are connected through a series of lateral headers that create a comprehensive collection system throughout the landfill. A slight vacuum applied to this network draws the gas into the system, preventing its escape into the atmosphere. Once collected, the raw landfill gas undergoes several cleaning and processing steps to remove impurities such as moisture, particulates, siloxanes, and hydrogen sulfide, which could damage equipment or reduce energy output quality.

“Instead of drilling for more natural gas, we're using landfill gas that's already in the environment and putting it to work. Together, we're turning waste into a clean energy resource that cuts emissions and reduces our reliance on fossil fuels.” – Ameresco representative discussing the Keller Canyon project

“Choosing Landfill Gas and Leachate …” from www.btlliners.com and used with no modifications.

Converting Methane to Renewable Natural Gas (RNG)

The transformation of raw landfill gas into pipeline-quality renewable natural gas represents the highest value end-product in the LFG-to-energy spectrum. This process requires additional purification steps beyond basic collection, including the removal of carbon dioxide, nitrogen, oxygen, and other trace compounds to achieve a methane concentration of over 95%. Advanced membrane separation technology, pressure swing adsorption, or amine scrubbing systems are employed to achieve this high level of purification. The resulting RNG is chemically identical to conventional natural gas, allowing it to be injected directly into existing pipeline infrastructure or compressed for use as vehicle fuel.

Key Technologies Making Conversion Possible

Several cutting-edge technologies have made landfill gas-to-energy projects increasingly efficient and economically viable. Gas analyzers continuously monitor methane content and system performance, ensuring optimal operation and safety. Regenerative thermal oxidizers destroy any remaining volatile organic compounds before gas is released. Advanced filtration systems using activated carbon and other media remove specific contaminants that could interfere with end-use applications. Computer monitoring systems provide real-time data on gas flow, quality, and system performance, allowing for immediate adjustments to maximize energy production while maintaining environmental compliance.

The Keller Canyon Success Story

The Keller Canyon Landfill in Pittsburg, California exemplifies the successful transformation of waste into renewable energy. This pioneering facility has become a showcase for how modern landfills can contribute to California's clean energy goals while reducing environmental impact. The project demonstrates how public-private partnerships can create infrastructure that serves both environmental and economic interests simultaneously.

“Climate Change: Keller Canyon Landfill …” from abc7news.com and used with no modifications.

Republic Services and Ameresco Partnership in Action

The collaboration between waste management leader Republic Services and renewable energy specialist Ameresco has created a model for effective landfill gas utilization. Republic Services, which operates the Keller Canyon Landfill, provides the raw material – landfill gas – while Ameresco contributes the technical expertise and infrastructure needed to convert this gas into pipeline-quality renewable natural gas. This partnership leverages the strengths of both organizations, with Republic's waste management experience complementing Ameresco's energy conversion capabilities. The successful implementation demonstrates how industry collaboration can accelerate the adoption of renewable energy technologies and create scalable solutions for waste-to-energy conversion.

Impressive Numbers: 4,500 Cubic Feet Per Minute Capacity

The Keller Canyon facility operates at a remarkable scale, processing approximately 4,500 cubic feet per minute of landfill gas. This substantial volume allows the plant to produce approximately 1 billion cubic feet of renewable natural gas annually – enough to meet the needs of thousands of California homes and businesses. The facility's design incorporates redundancy and scalability, allowing it to maintain consistent output despite variations in landfill gas production. By operating at this scale, the project achieves economies that make renewable energy production cost-competitive with conventional fossil fuel sources.

First RNG Interconnection with PG&E's Pipeline System

A groundbreaking aspect of the Keller Canyon project is its status as the first renewable natural gas interconnection from a landfill gas project for Pacific Gas and Electric Company (PG&E). This direct pipeline connection allows the renewable natural gas produced at the landfill to be seamlessly integrated into California's existing natural gas infrastructure. The interconnection required meeting stringent gas quality standards and regulatory requirements, establishing a precedent for future projects throughout the state. By demonstrating successful integration with a major utility's distribution system, the project has created a pathway for other landfills to contribute to California's renewable energy portfolio.

Measuring the Environmental Impact

The environmental benefits of landfill gas-to-energy projects extend far beyond the immediate reduction of methane emissions. When measured comprehensively, these projects create cascading positive impacts throughout our ecosystem and economy. The Keller Canyon facility serves as an excellent case study for quantifying these benefits in real-world applications.

62,000 Metric Tons of Carbon Emissions Reduced Annually

According to project data, the Keller Canyon LFG-to-energy facility reduces annual carbon emissions by approximately 62,000 metric tons. This figure represents the combined effect of preventing methane release and displacing fossil fuel consumption with renewable energy. The calculation accounts for the global warming potential of methane over a 100-year timeframe, capturing the true climate impact of the conversion. This substantial reduction makes the facility one of California's most effective single-site climate mitigation projects, demonstrating how infrastructure investments can yield significant environmental returns.

Equivalent to Taking 30,000 Cars Off the Road

To put the environmental impact in perspective, the annual emission reductions from Keller Canyon are equivalent to removing approximately 30,000 passenger vehicles from California's highways. This comparison helps visualize the magnitude of the climate benefit in terms familiar to most people. The emissions prevented represent more than just numbers on a page—they translate to measurable improvements in air quality and public health throughout the region. As vehicle emissions represent one of California's largest sources of greenhouse gases, this equivalency demonstrates how waste management can contribute significantly to the state's climate goals.

Displacing 7.5 Million Gallons of Diesel Fuel

The renewable natural gas produced at Keller Canyon displaces approximately 7.5 million gallons of diesel fuel annually. This substitution not only reduces carbon dioxide emissions but also eliminates the nitrogen oxides, particulate matter, and other pollutants associated with diesel combustion. For regions struggling with air quality challenges, this displacement represents a substantial health benefit beyond climate considerations. The renewable natural gas can be used in existing natural gas vehicles or infrastructure without modification, making it an immediately deployable solution for reducing transportation emissions.

“Solar Energy and Job Creation” from green.org and used with no modifications.

Economic Benefits Beyond Environmental Gains

While environmental improvements drive much of the interest in LFG-to-energy projects, the economic advantages create a compelling business case for their continued expansion. These facilities demonstrate how sustainability initiatives can generate positive financial returns while addressing climate challenges. For more details on the benefits of these projects, check out this article on landfill gas-to-energy solutions.

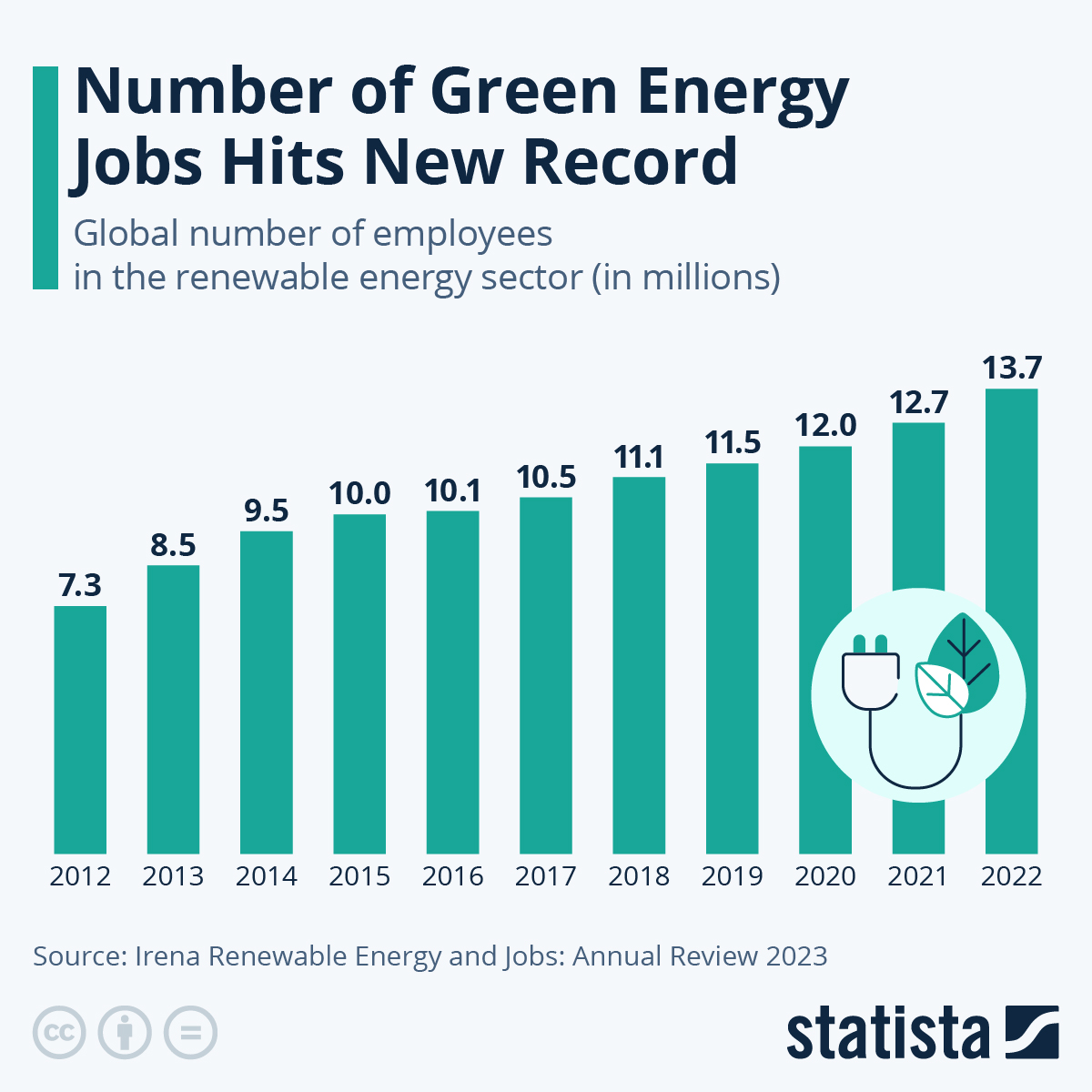

Job Creation in Green Energy Sector

The development, construction, and operation of landfill gas energy projects create high-quality jobs across multiple sectors. Each facility requires engineers, construction workers, equipment operators, and maintenance technicians during both the installation and operational phases. The Keller Canyon project alone created dozens of construction jobs during development and maintains several permanent positions for ongoing operations. Unlike some other energy projects, LFG facilities provide employment opportunities in both urban and rural communities where landfills are located, spreading economic benefits across diverse geographic areas.

“Chart: Number of Green Energy Jobs Hits …” from www.statista.com and used with no modifications.

Revenue Generation from Previously Wasted Resources

LFG-to-energy projects transform what was once a liability—methane gas that required management and control—into a valuable commodity that generates revenue. Landfill operators can create new income streams by selling the renewable natural gas or electricity produced from their facilities. This revenue helps offset the costs of environmental compliance and can improve the overall economics of waste management operations. For municipal landfills, these projects can reduce the financial burden on local governments and taxpayers while contributing to sustainability goals.

Supporting California's Renewable Energy Economy

California's leadership in renewable energy has created a robust economic ecosystem around clean power generation, and LFG projects strengthen this growing sector. The integration of landfill gas into the renewable energy portfolio diversifies the state's clean energy sources, reducing dependence on intermittent resources like solar and wind. This diversification improves grid reliability while maintaining environmental benefits. Additionally, as California implements policies that place a premium on renewable fuels, the economic value of LFG-derived energy continues to increase, making these projects increasingly attractive investments.

Other Successful LFG Projects Across America

While Keller Canyon represents a cutting-edge example of LFG utilization, successful projects across the country demonstrate the versatility and scalability of this technology. These diverse applications show how landfill gas can be adapted to meet specific local needs and opportunities.

BMW Manufacturing's Innovative Approach in South Carolina

The BMW manufacturing plant in Spartanburg, South Carolina provides an innovative example of direct industrial use of landfill gas. This facility receives gas via a 9.5-mile pipeline from a nearby landfill, using it to power turbines that generate approximately 30% of the plant's electricity needs. The system reduces carbon dioxide emissions by about 92,000 tons annually while providing a reliable energy source for manufacturing operations. This public-private partnership demonstrates how industrial facilities can incorporate renewable energy into their operations while reducing both emissions and energy costs.

“BMW Manufacturing …” from www.linkedin.com and used with no modifications.

University of New Hampshire's EcoLine™ Cogeneration System

The University of New Hampshire's EcoLine™ system stands out as an educational institution leveraging landfill gas for campus energy needs. This cogeneration system delivers processed landfill gas through a 12.7-mile pipeline from a regional landfill to the university's power plant. The gas provides both electricity and heating for the campus, meeting up to 85% of the university's energy requirements. Beyond the environmental and economic benefits, the system serves as a living laboratory for students studying renewable energy and environmental engineering.

“Energy | Sustainability” from www.unh.edu and used with no modifications.

Different Applications: Electricity, Heating, and Vehicle Fuel

Landfill gas projects across America showcase the versatility of this renewable resource beyond pipeline injection. Some facilities use internal combustion engines or turbines to generate electricity that's fed directly into the local grid. Others direct the gas to nearby industrial facilities where it replaces natural gas in boilers, kilns, or other thermal applications. Increasingly, landfill gas is being processed into transportation fuel for natural gas vehicles, particularly for fleet applications like buses or waste collection trucks. This diversity of end uses allows each project to be optimized for local conditions and market opportunities. For more detailed data on these projects, you can visit the EPA's landfill gas energy project data.

- Electricity generation – Most common application using engines, turbines, or fuel cells

- Direct thermal use – Replacing natural gas in industrial processes

- Combined heat and power – Generating electricity while capturing waste heat

- Renewable natural gas – Pipeline injection for multiple downstream applications

- Vehicle fuel – Compressed or liquefied for transportation applications

How California Is Leading the Renewable Energy Revolution

California has established itself as a national leader in renewable energy adoption through ambitious policies, innovative financing mechanisms, and strong public support. The state's approach to landfill gas utilization reflects this broader commitment to developing diverse clean energy resources.

State Policies Supporting LFG-to-Energy Projects

California's policy framework provides multiple incentives for landfill gas energy development. The Low Carbon Fuel Standard (LCFS) creates financial value for fuels that reduce transportation-related greenhouse gas emissions, making RNG from landfills particularly valuable in the transportation sector. The state's cap-and-trade program establishes a price on carbon emissions, improving the economics of emission reduction projects like LFG conversion. Additionally, California's Renewable Portfolio Standard requires utilities to procure increasing percentages of their electricity from renewable sources, creating demand for LFG-generated power. These complementary policies work together to accelerate the transformation of the state's landfills into renewable energy assets.

60% Renewable Energy by 2030 Goal

California has established one of America's most ambitious renewable energy targets—60% renewable electricity by 2030. This goal drives investment in all forms of renewable energy, including landfill gas recovery systems. For utilities working to meet these requirements, LFG-to-energy projects offer advantages over some other renewable sources, particularly the ability to provide baseload power that isn't dependent on weather conditions. The predictable generation profile of landfill gas systems complements intermittent resources like solar and wind, helping to maintain grid stability as renewable penetration increases. By incorporating landfill gas into its renewable portfolio, California is demonstrating a practical approach to achieving high renewable energy percentages.

The 60% target represents a milestone on California's journey toward a fully decarbonized electricity system. Each landfill gas project contributes incrementally toward this goal while providing other environmental benefits. With approximately 300 landfills across the state, the potential for expansion remains significant. Learn more about generating electricity from waste and its impact on achieving sustainability goals.

California's approach involves not just setting targets but also creating the regulatory framework and market mechanisms necessary to achieve them. The state's energy agencies work closely with landfill operators, utilities, and technology providers to identify and remove barriers to project development.

“California's leadership in renewable energy policy has created a fertile environment for landfill gas-to-energy projects. The state's combination of carbon pricing, renewable energy standards, and fuel-specific incentives has established economic conditions where capturing methane makes both environmental and financial sense.” – California Air Resources Board

Carbon Neutrality by 2045 Target

California's Executive Order B-55-18 established the goal of economy-wide carbon neutrality by 2045, requiring deep decarbonization across all sectors. Landfill gas projects contribute to this ambitious target by addressing one of the most potent greenhouse gases and converting it into renewable energy that displaces fossil fuels. As California works toward carbon neutrality, the state is increasingly focused on negative emission technologies and approaches that actively remove carbon from the atmosphere—making improved landfill gas capture particularly valuable as both an emission reduction and potential carbon negative strategy when combined with carbon capture technologies.

The Future of Landfill Gas Energy in America

As technology advances and climate policies strengthen, landfill gas-to-energy systems are poised for significant growth and evolution. The coming decade will likely see expanded adoption alongside technological improvements that increase efficiency and reduce costs. This renewable energy resource, hidden in plain sight at thousands of landfills nationwide, represents a substantial opportunity for sustainable development.

Technological Improvements on the Horizon

Emerging technologies promise to make landfill gas recovery more efficient and economical in the coming years. Advanced monitoring systems using machine learning algorithms can optimize gas collection by predicting production rates and identifying collection inefficiencies. New biological treatments may enhance methane generation within landfills, increasing gas yields from existing waste. Improved separation technologies are reducing the cost of upgrading landfill gas to pipeline quality, making RNG production viable at smaller landfills.

The integration of solar generation at landfill sites represents another promising direction, creating dual-use renewable energy facilities that maximize clean energy production from land with limited alternative uses. Some developers are exploring innovative approaches that combine landfill gas collection with carbon capture technologies, potentially creating carbon-negative energy systems that actively reduce atmospheric greenhouse gas concentrations.

Expansion Potential to Thousands of Landfills Nationwide

According to the EPA's Landfill Methane Outreach Program, approximately 550 landfills across the United States currently operate LFG energy projects, but an additional 470 landfills present attractive opportunities for project development. These candidate landfills could generate approximately 17 billion kilowatt-hours of electricity annually, enough to power more than 1.5 million homes. For more information on how waste can be converted into energy, visit this guide on generating electricity from waste.

LFG Project Status | Number of Landfills | Energy Potential |

|---|---|---|

Operational Projects | 550 | 16 billion kWh/year (current) |

Candidate Landfills | 470 | 17 billion kWh/year (potential) |

Total Opportunity | 1,020 | 33 billion kWh/year |

The expansion potential extends beyond electricity generation to include direct use applications and renewable natural gas production. As natural gas pipeline infrastructure continues to expand in rural areas, more landfills gain access to interconnection points that make RNG production economically viable. Additionally, many existing projects using older technologies present opportunities for upgrades that could significantly increase energy output.

The geographical distribution of landfills across all 50 states means that LFG-to-energy expansion can provide renewable energy benefits nationwide, not just in regions traditionally associated with renewable resources. This democratization of clean energy production strengthens energy security while spreading economic benefits across diverse communities.

What This Means for Our Clean Energy Future

Landfill gas-to-energy projects represent a crucial component of America's transition to a low-carbon energy system. Unlike some renewable resources that require entirely new infrastructure, LFG utilization leverages existing waste management systems and natural gas infrastructure, reducing implementation barriers. The baseload nature of landfill gas generation complements intermittent renewables like solar and wind, helping to maintain grid stability during the transition to higher renewable penetration.

Perhaps most importantly, LFG projects demonstrate how environmental challenges can be transformed into opportunities through innovation and collaboration. By capturing a potent greenhouse gas and converting it into useful energy, these systems embody the circular economy principles that will be essential for sustainable development in the 21st century.

Frequently Asked Questions

As landfill gas-to-energy systems become more prevalent, many common questions arise about their operation, benefits, and limitations. Understanding these aspects helps communities and stakeholders evaluate potential projects and their impacts.

The following questions address the most common inquiries from those interested in LFG energy projects, from basic technical aspects to economic and environmental considerations.

“The questions we receive most frequently about landfill gas projects reflect growing public interest in renewable energy solutions that offer multiple benefits. People want to understand not just how the technology works, but how it might benefit their communities economically and environmentally.” – EPA Landfill Methane Outreach Program

These questions and answers provide a foundation for understanding the key aspects of landfill gas energy projects and their role in our renewable energy future.

What exactly is landfill gas and why is it valuable?

Landfill gas is a natural byproduct of organic waste decomposition in an oxygen-limited environment. It typically consists of about 50% methane and 50% carbon dioxide, along with small amounts of non-methane organic compounds. Its value comes primarily from the methane content, which is the same primary component found in natural gas. When captured, this methane can be used as a renewable fuel source instead of escaping as a potent greenhouse gas. Unlike fossil natural gas, landfill gas is considered renewable because it's continuously generated from recently deposited organic waste rather than being extracted from ancient deposits.

How much energy can a typical landfill produce through LFG conversion?

A typical medium-sized landfill receiving about 1 million tons of waste annually can generate enough landfill gas to produce approximately 5 megawatts of electricity, sufficient to power about 4,000-5,000 homes. Larger landfills can produce significantly more energy, with some facilities generating over 20 megawatts. When converted to renewable natural gas instead of electricity, a medium-sized landfill might produce 1,000-2,000 MMBtu per day, equivalent to about 8,000-16,000 gallons of diesel fuel. The energy potential depends on several factors including waste composition, landfill age, climate conditions, and the efficiency of the collection system.

Are there health benefits to communities near landfills with LFG systems?

Yes, landfill gas collection systems provide significant health benefits to nearby communities by reducing odors and air pollutants. Uncaptured landfill gas contains numerous non-methane organic compounds (NMOCs) including volatile organic compounds (VOCs) and hazardous air pollutants that can cause respiratory irritation and other health issues. By capturing these gases before they escape, LFG systems improve local air quality and reduce odor complaints that often affect neighborhoods near landfills.

Additionally, when landfill gas replaces other fuels like coal or diesel, it reduces emissions of particulate matter, sulfur dioxide, and nitrogen oxides that contribute to respiratory diseases. Communities with environmental justice concerns particularly benefit from these improvements in local air quality.

How much does it cost to install LFG-to-energy technology at a landfill?

The installation costs for landfill gas energy projects vary widely depending on the size, type, and complexity of the system. A basic electricity generation project using internal combustion engines might cost $2-3 million per megawatt of generation capacity. More complex systems for producing renewable natural gas for pipeline injection typically cost $10-20 million or more, depending on gas processing requirements and pipeline interconnection distances. While these capital costs are substantial, operational costs are relatively low, and revenue from energy sales combined with environmental credits can provide attractive returns on investment. Many projects achieve payback periods of 3-7 years depending on energy prices and available incentives.

Can homeowners purchase renewable natural gas from these landfill projects?

Yes, homeowners can increasingly purchase renewable natural gas through various utility programs, though the physical molecules might not come directly from landfills. When RNG is injected into natural gas pipelines, it mixes with conventional natural gas in the distribution system. Utilities typically offer RNG through book-and-claim systems where customers can purchase environmental attributes associated with RNG production, similar to renewable electricity certificates. Several California utilities now offer voluntary RNG purchase programs where customers can choose to pay a premium to support renewable gas production. These programs are expanding as consumer interest in renewable energy options grows and utilities seek to reduce the carbon intensity of their gas supply.

The transformation of California's landfills into clean energy production facilities represents one of the most practical and impactful approaches to addressing climate change while creating economic value. By capturing what was once wasted and converting it into renewable energy, these projects demonstrate the power of innovative thinking applied to environmental challenges.

For communities seeking to reduce their carbon footprint while supporting local economic development, landfill gas energy projects offer a proven solution with multiple benefits. The success stories from California's LFG-to-energy transformation provide valuable lessons that can be applied nationwide as we work toward a more sustainable energy future.

To learn more about how landfill gas-to-energy projects are revolutionizing waste management and renewable energy production across America, visit Ameresco's renewable energy solutions page for case studies and implementation resources.

California has been at the forefront of adopting innovative solutions to manage landfill gas emissions. The state has implemented numerous landfill gas-to-energy solutions that convert harmful emissions into usable energy, significantly reducing the environmental impact. These initiatives not only help in managing waste effectively but also contribute to the state's renewable energy goals.

The Future of Sustainable Bio-based Materials and Products

Bio-based materials are products and materials made from renewable biological resources like plants, animals, and microorganisms. They are a sustainable alternative to traditional fossil-fuel-based products, offering advantages such as a smaller carbon footprint and reduced reliance on finite resources. Common examples include timber, hemp, and bio-based plastics like polylactic acid (PLA), and they are used […]

Best Low Carbon Farming Practices & Techniques

Farmers are turning to low carbon techniques like no-till farming and precision agriculture to combat climate change. These practices not only reduce emissions but also improve soil health and farm profitability, offering a resilient future for agriculture as weather patterns grow increasingly unpredictable…

Which Gas is Produced from Landfill Waste: The Gas that Trash Produces…

Discover which gas is produced from landfill waste and understand its environmental impact and potential energy use. Explore landfill gas management.

Biogas Innovators Take Centre Stage: The World Biogas Awards 2024

Since 2011, a prestigious ceremony has been quietly moving the world on a path back to sustainability – not with flashy gadgets or social media trends, but with something far more fundamental: biogas innovation. The annual AD and Biogas Industry Awards, held in Birmingham, UK, celebrate the brilliance behind this renewable energy source, recognizing the […]