Biomethane's carbon footprint varies greatly but is generally much lower than that of fossil natural gas, as its carbon is from recent plant matter (short carbon cycle). Production using organic waste feedstock and integrated systems often yields substantial greenhouse gas (GHG) reductions, creating renewable energy and biofertilizers, but the overall impact depends heavily on site-specific factors.

Summary

- By 2050, biomethane production combined with carbon capture technology could remove up to 3.5 Gt of greenhouse gas emissions from the atmosphere.

- When used instead of conventional natural gas, biomethane with CCS could save almost 8 Gt of GHG emissions per year by 2050.

- The carbon footprint of biomethane can vary greatly depending on the production method, with anaerobic digestion of waste streams usually having the lowest carbon intensity.

- Integrating carbon capture turns biomethane from carbon-neutral to carbon-negative, making it a rare technology that actively removes CO2 from the atmosphere.

- Consulting services are available at IPPTS Associates to help organisations implement sustainable biomethane production systems that minimize carbon footprints and maximise energy output.

As the world transitions to cleaner energy, we need solutions that not only reduce emissions but also actively remove carbon from our atmosphere. Biomethane is at the forefront of this revolution, providing a way to produce carbon-negative energy when combined with the right technologies. It's important to understand the carbon footprint implications of different biomethane production methods when making decisions about sustainable energy infrastructure.

Biomethane: The Green Energy Solution Reducing Carbon Emissions Today

Biomethane is one of our most adaptable renewable energy sources, able to effortlessly integrate into existing natural gas infrastructure while significantly cutting greenhouse gas emissions. Unlike fossil natural gas, biomethane comes from organic materials that have recently absorbed carbon from the atmosphere, resulting in a short carbon cycle that greatly reduces overall emissions. The climate advantage is especially noticeable when biomethane is generated from waste streams that would otherwise emit methane—a powerful greenhouse gas with 28 times the warming potential of CO2—straight into the atmosphere. CleanTech Bioenergy Solutions has been a trailblazer in the development of advanced biomethane production systems that maximise these climate advantages while providing dependable, renewable energy for a variety of uses.

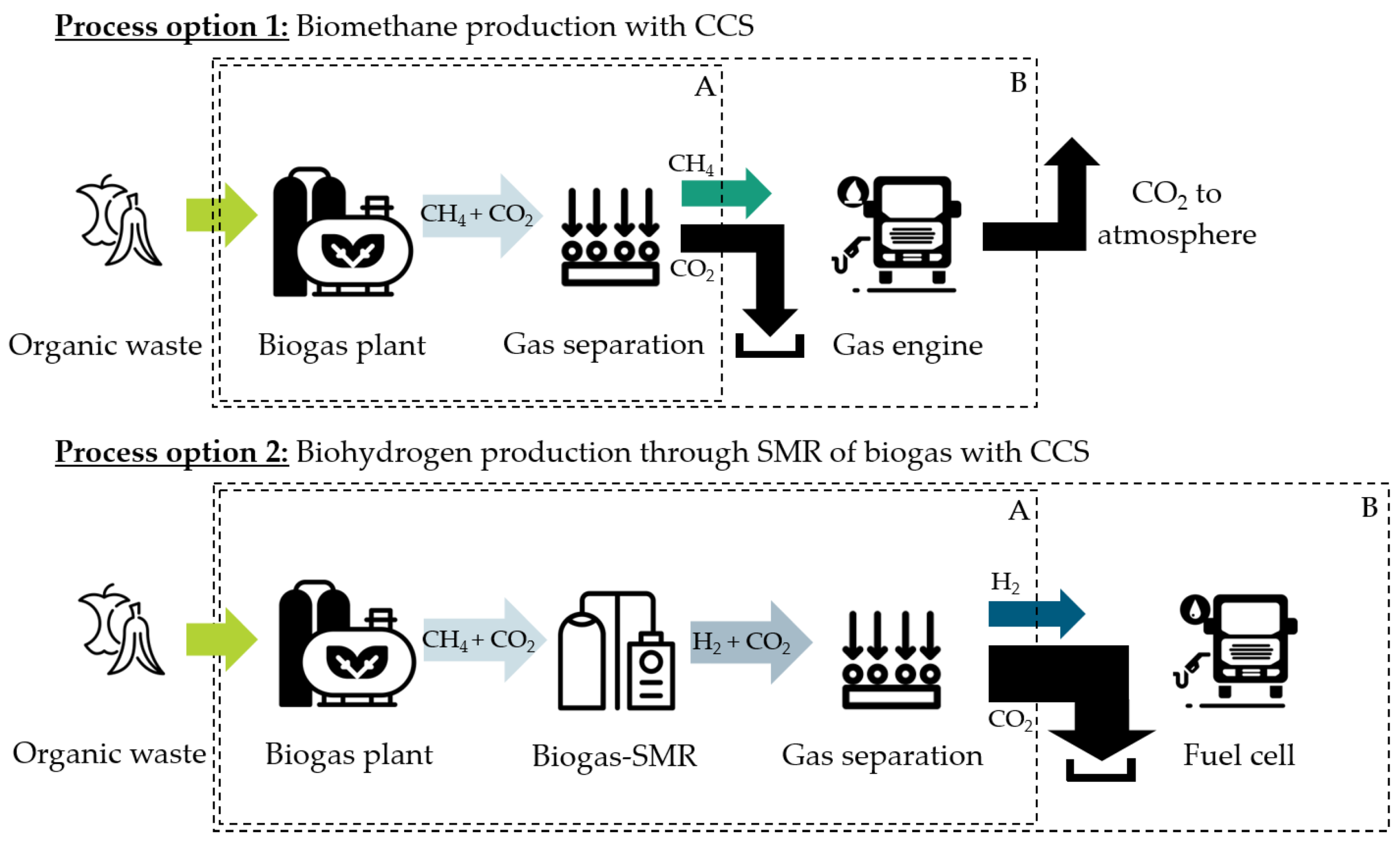

“Biogas Plants as BECCS Facilities …” from www.mdpi.com and used with no modifications.

Reducing Carbon Emissions with Biomethane Production

Biomethane's ability to reduce carbon emissions is rooted in its unique nature, which sets it apart from fossil fuels. Instead of releasing carbon that has been stored underground for millions of years, biomethane production harnesses the continuous carbon cycle, using carbon that plants have recently extracted from the atmosphere.

Comparing the Carbon Cycles of Biomethane and Fossil Natural Gas

Traditional natural gas, when burned, releases carbon that has been trapped for thousands of years. This results in a net increase in atmospheric carbon dioxide levels. Biomethane, on the other hand, only releases carbon that was recently absorbed by the organic materials from which it is derived. This cyclical process essentially creates a closed carbon loop. The carbon neutrality of biomethane is further improved when it is derived from waste streams that would otherwise produce methane emissions as they decompose. Agricultural by-products, food waste, manure, and sewage are all excellent sources because their conversion to biomethane production prevents uncontrolled emissions while also generating valuable renewable energy.

Life Cycle Assessment: From Raw Materials to End Use

In order to fully grasp the carbon footprint of biomethane, it's necessary to look at the entire production process using life cycle assessment (LCA) methodology. This holistic approach takes into account emissions from raw material collection, transportation, processing, upgrading, distribution, and end use. The carbon intensity of biomethane is influenced by a number of factors, including the type of raw material, collection methods, energy requirements for processing, methane leakage rates, and transportation distances. Biomethane production systems, when properly managed, can achieve carbon intensities that are 60-80% lower than those of fossil natural gas.

- Origin of feedstock (waste streams vs. dedicated crops)

- Energy consumed in production (renewable vs. fossil-based)

- Transportation needs (local vs. distant production)

- Prevention of methane leakage (system integrity)

- Management of digestate (appropriate use as fertiliser)

Modern biomethane facilities include systems for detecting methane leaks, use renewable energy for processing, and manage digestate optimally to reduce emissions throughout the production process. The outcome is a renewable gas with a significantly lower carbon footprint than traditional fossil alternatives.

Carbon Capture Offers the Potential for Negative Carbon Emissions

“Carbon Capture Technology | HoSt Group” from www.host-bioenergy.com and used with no modifications.

The most significant recent advancement in biomethane production is the addition of carbon capture technologies. This change takes biomethane from being carbon-neutral to being carbon-negative. Raw biogas usually contains 30-50% CO2 in addition to methane. Traditional methods of upgrading simply release this CO2 during the purification process. However, newer, more advanced systems capture this CO2 stream and either store it underground or use it in industrial applications. This creates a real carbon sink. This combination of biomass-based energy with carbon capture and storage (BECCS) is one of the few technologies that can provide negative emissions. This means it removes more carbon from the atmosphere than it releases.

Biomethane production with carbon capture has a significant technical potential for reducing greenhouse gases. Current projections indicate that as much as 3.5 Gt of CO2 could be removed each year by 2050 through widespread implementation, making a significant contribution to efforts to stabilise the climate. These carbon-negative pathways will be critical for offsetting difficult-to-reduce emissions in other sectors and achieving net-zero targets.

How Biomethane Production Methods Impact Carbon Dioxide Emissions

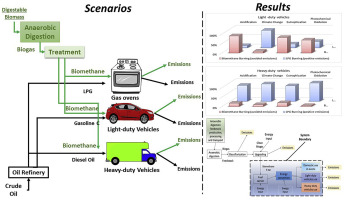

Biomethane’s carbon footprint can vary greatly based on the production method used. Each method has unique benefits, challenges, and emission profiles. It’s important to understand these differences to create the most effective biomethane strategies for the environment, such as the integration of biogas systems into the energy system.

From Small Farms to Big Industry: Anaerobic Digestion

Anaerobic digestion (AD) is the most popular technology for producing biomethane across the globe. It transforms organic materials into biogas through the process of microbial decomposition in environments without oxygen. This adaptable method can be used on scales as small as a farm digester processing manure or as large as an industrial facility handling municipal waste streams. The carbon footprint of AD systems is heavily influenced by the type of feedstock used. Systems that use waste generally perform better than those that use dedicated energy crops. AD systems can achieve impressively low or even negative carbon intensities when they use waste streams that would otherwise produce methane emissions during decomposition. This doesn't even take into account the benefits of displacing fossil fuels.

The carbon emissions profile can be improved even further when the nutrient-rich byproduct of AD, known as digestate, is effectively managed and used as a replacement for fertiliser, thus reducing the need for carbon-intensive synthetic fertilisers. Small-scale, decentralised AD systems also offer additional carbon benefits by reducing the need for transportation, especially when processing high-moisture feedstocks like manure, which would otherwise be expensive and carbon-intensive to transport over long distances.

Gasification: How Solid Biomass Becomes Clean Gas

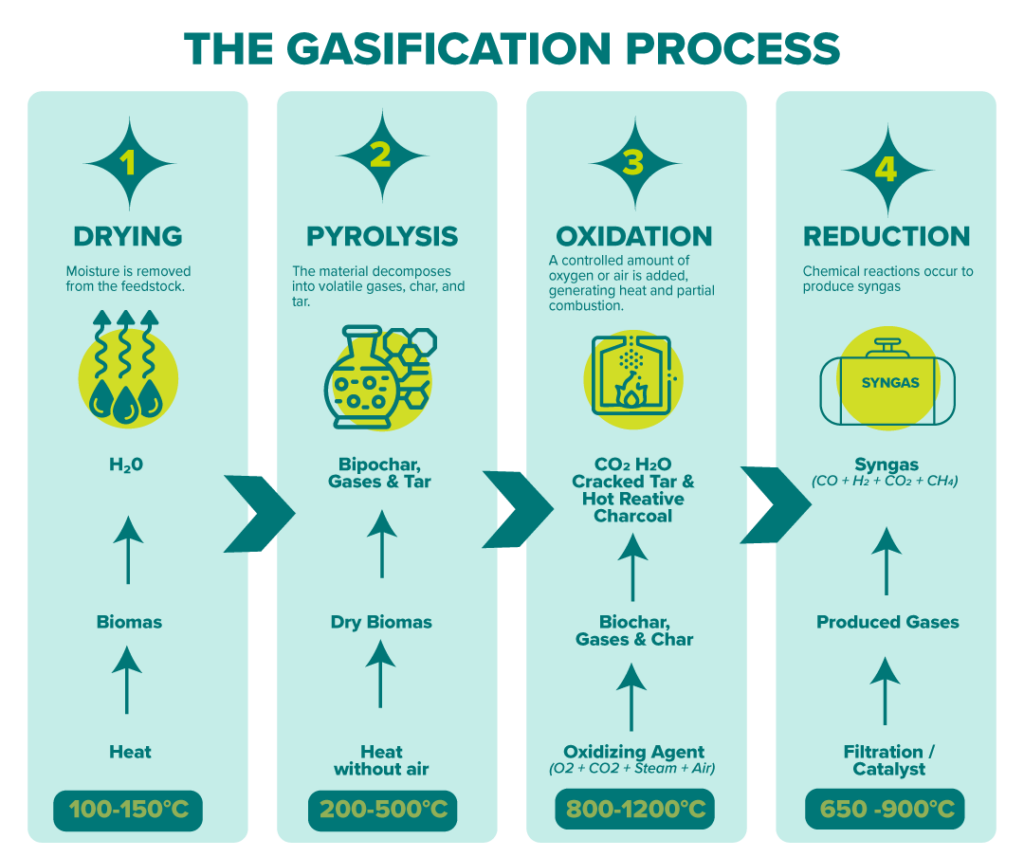

“A Quick Guide to Gasification | Ivys” from ivysads.com and used with no modifications.

Gasification technology allows us to transform solid biomass feedstocks into syngas, which can then be further converted into biomethane. This thermochemical process operates at high temperatures (usually between 700 and 1200°C) in a controlled oxygen environment. It breaks down complex carbon molecules into simpler gaseous compounds. Gasification is particularly effective at processing woody, lignocellulosic materials that are unsuitable for traditional anaerobic digestion. This expands the range of potential biomethane feedstocks. The carbon footprint of gasification systems is primarily determined by process efficiency and energy requirements. This is because the high-temperature process typically requires a significant energy input.

Massive gasification plants can achieve scale economies that enhance carbon performance, especially when combined with carbon capture systems that sequester CO₂ produced during the conversion process. The greatest technical potential for biomethane with carbon capture and storage (CCS) comes from these massive gasification plants, which could become regional biomethane production centres where suitable infrastructure exists for biomass transport, gas distribution, and CO₂ sequestration.

Power-to-Gas: Merging Hydrogen and Captured CO₂

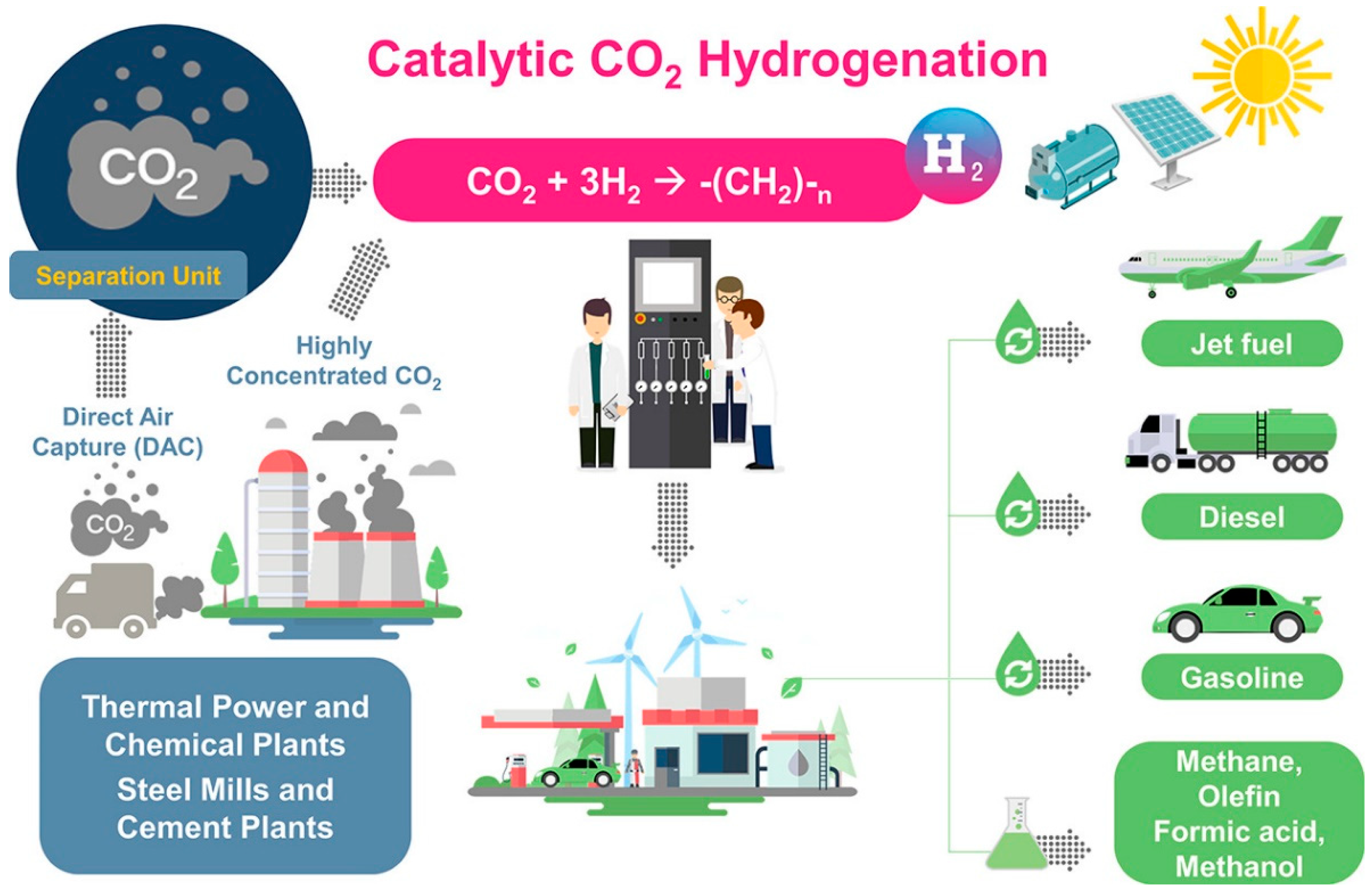

“Efficient Utilization of Carbon Dioxide …” from www.mdpi.com and used with no modifications.

The rising power-to-gas pathway is an inventive method for biomethane production that uses renewable electricity to improve carbon performance. This technique uses renewable electricity to create hydrogen through electrolysis, then merges this hydrogen with CO₂ (usually captured from biogas upgrading) to create methane through methanation. This method effectively stores renewable electricity as methane that can be injected into existing gas infrastructure, offering a solution to renewable energy intermittency problems.

Power-to-gas systems are great for the environment when they're powered by excess renewable electricity that would otherwise be wasted. Using hydrogen to boost traditional biomethane production can significantly reduce the carbon footprint of energy production and use. This is especially true when it captures CO₂ that would otherwise be released into the air. Research shows that while production costs may go up compared to standard biomethane methods, the costs of this boosted production are usually lower than many direct power-to-gas concepts where CO₂ has to be captured specifically for methane synthesis.

Which Production Method is the Most Eco-friendly?

In terms of carbon footprint, waste-based anaerobic digestion often comes out on top for high-moisture feedstocks. This is especially true when dealing with waste streams that have a high potential for methane emissions, such as manure or food waste. For woody biomass and agricultural residues, gasification with carbon capture integration usually results in the lowest life-cycle emissions. Power-to-gas methods also have potential in terms of carbon performance when using surplus renewable electricity, but these are currently economically challenging in many markets. For more on methane emissions, explore methane capture systems.

The best method ultimately depends on specific regional conditions, including available raw materials, existing infrastructure, energy prices, and policy frameworks. A comprehensive carbon assessment should consider not only direct emissions but also indirect factors like land-use changes, transportation requirements, and displaced emissions from alternative waste management or energy production systems.

Understanding Biomethane's Impact on the Climate

“Environmental impact assessment of end …” from www.sciencedirect.com and used with no modifications.

By measuring the carbon reduction potential of biomethane, we can see how important it is in strategies to mitigate climate change. Many studies have shown that the climate can greatly benefit from the use of biomethane on a large scale, especially when it is used in conjunction with carbon capture technologies.

Reducing Greenhouse Gas Emissions by 3.5 Gt by 2050

Studies show that biomethane production with integrated carbon capture and storage (CCS) has the technical potential to remove up to 3.5 gigatonnes of greenhouse gas emissions from the atmosphere annually by 2050. This impressive figure represents about 10% of the emissions reductions needed from the energy sector to align with international climate goals. The combination of bioenergy with carbon capture creates one of the few viable negative emissions technologies at our disposal—technologies that will be crucial for balancing residual emissions in hard-to-abate sectors like heavy industry, aviation, and shipping.

8 Gt Annual Savings When Replacing Natural Gas

When we consider the direct removal of carbon through CCS and the emissions avoided by displacing fossil natural gas, the climate benefit becomes even more significant. Research suggests that annual greenhouse gas emission savings could reach nearly 8 gigatonnes by 2050 if we systematically replace conventional natural gas with biomethane production integrated with carbon capture.

By capturing biogenic carbon and simultaneously avoiding fossil emissions, biomethane becomes one of our most potent tools for mitigating climate change. The potential for emissions reduction is enormous, representing roughly 25% of current global energy-related emissions. This underscores biomethane's potential to play a significant role in decarbonising efforts across various sectors.

Comparing Carbon Intensity Across Various Feedstocks

Biomethane's carbon intensity can vary widely depending on the feedstock used, but waste-based pathways generally have better climate performance. Recent life cycle assessments show that biomethane from food waste and manure can achieve carbon intensities as low as 10-15 gCO2e/MJ, compared to about 70-80 gCO2e/MJ for conventional natural gas. This significant difference underscores the importance of selecting the right feedstock to maximise climate benefits. For more insights on innovations in this field, explore the Biogas Innovation Awards 2024.

Comparing Carbon Intensity by Feedstock (gCO2e/MJ)

Food Waste: 10-15

Manure: 5-20 (can be negative with methane avoidance)

Sewage Sludge: 20-35

Agricultural Residues: 25-40

Energy Crops: 35-60

Conventional Natural Gas: 70-80

Manure, which is rich in methane, can actually yield negative carbon intensity values (from -10 to -120 gCO2e/MJ in some instances) when the methane emissions that would have been released during traditional waste management are taken into account. This makes projects that convert livestock waste into biomethane particularly appealing from both an environmental and economic standpoint, especially when carbon credits or low-carbon fuel standards are available.

Practical Successes in Reducing Carbon

Not only does biomethane promise theoretical benefits for reducing carbon, but it has also proven its worth in practice. Projects around the globe have successfully implemented biomethane, showing that well-planned initiatives can have a significant impact on the climate.

Europe's Biogas Facilities Pave the Way

Europe has taken the lead in the development of biomethane, with countries such as Germany, Italy, and Sweden proving the potential of this technology to reduce carbon on a large scale. The biomethane industry in Sweden has achieved particularly notable results, with over 60% of the gas used in the transport sector now coming from biomethane sources, which greatly reduces the carbon intensity of its vehicle fleet. The country's strategic focus on biomethane from sewage sludge and food waste has created a circular economy approach to energy that offers significant climate benefits.

Denmark has led the way in combining carbon capture with biogas upgrading, showing how biomethane can move from being carbon-neutral to carbon-negative. The Nature Energy Korskro facility captures CO₂ from biogas upgrading and provides it to industrial users, preventing fossil CO₂ emissions while creating renewable gas. This plant handles more than 300,000 tonnes of organic waste each year, producing enough biomethane to warm 7,500 houses while having a net carbon footprint that is roughly 50% less than that of traditional biogas activities.

From Agricultural Waste to Energy: How Farms Benefit from Lower Carbon Emissions

Biomethane has become a popular solution for the agricultural industry to manage waste and lower their carbon footprint. Dairy farms across America are now using anaerobic digesters to capture methane from manure that would otherwise be released into the air. One of the largest farm-based digesters is operated by Fair Oaks Farms in Indiana. They process manure from 36,000 cows to produce biomethane, which fuels their milk delivery trucks. This self-sufficient system decreases the farm's carbon footprint by around 43,000 tonnes of CO₂e every year. This is equivalent to taking over 8,000 cars off the road.

Agricultural facilities offer a variety of carbon advantages: preventing methane emissions from manure storage, replacing fossil fuels, decreasing the need for synthetic fertilisers through the application of digestate, and reducing transportation emissions by producing energy on-site. This holistic method shows how well-planned biomethane systems can tackle many aspects of agricultural carbon footprints at the same time.

Urban Waste Conversion Initiatives

As a solution to both waste management and carbon reduction, biomethane is gaining popularity among cities across the globe. The East Bay Municipal Utility District, located in Oakland, California, has launched a groundbreaking initiative that redirects food waste from landfills to its wastewater treatment digesters. This has led to an estimated 190% increase in biomethane production and has prevented methane emissions from landfills. Currently, the facility produces more energy than it uses, reaching carbon-neutral operation and supplying the local grid with renewable electricity.

The Severn Trent Green Power facility in the UK annually processes more than 50,000 tonnes of food waste from household collections. This process produces biomethane for grid injection and reduces the region's waste management carbon footprint by about 38,000 tonnes CO₂e each year. These municipal projects show how urban centres can turn waste liabilities into renewable energy assets and significantly reduce their carbon footprints.

The Revolutionary Pairing of Biomethane and Carbon Capture

Pairing carbon capture technologies with biomethane production has revolutionised the renewable energy sector by turning a carbon-neutral fuel into a carbon-negative energy solution. This game-changing combination is anticipated to be instrumental in achieving net-zero emissions targets.

The Role of Carbon Capture in Making Biomethane Carbon Negative

During the process of biomethane production, methane is naturally separated from carbon dioxide. In traditional systems, this CO₂—which constitutes 30-50% of raw biogas—is simply released into the atmosphere. Although this CO₂ is biogenic (meaning it was recently absorbed from the atmosphere by plants), capturing and storing it creates a real carbon sink. When this captured biogenic CO₂ is permanently taken out of the carbon cycle through geological storage, the result is a negative emissions pathway. This pathway actively decreases levels of carbon in the atmosphere while generating renewable energy.

The numbers are convincing: for each unit of biomethane produced and utilised, about 0.5-1 units of CO₂ can potentially be captured and stored. This equates to about 1.8-2.8 tonnes of CO₂ eliminated per tonne of biomethane produced when considering both the carbon capture advantage and the displacement of fossil fuels. There are few other renewable energy technologies that offer this dual climate benefit of both displacing fossil fuels and actively removing carbon from the atmosphere.

Technical Considerations for CCS Integration

Integrating carbon capture with biomethane production necessitates particular technical considerations to optimise both operational and carbon efficiency. The CO₂ stream from biogas upgrading is quite pure (usually 95-99% CO₂ after dehydration), making it one of the most cost-effective carbon capture opportunities available, compared to more diluted sources like power plant flue gases. Important technical considerations include gas cleanup to eliminate trace contaminants, CO₂ transportation compression systems, and either a connection to CO₂ transport infrastructure or on-site utilisation pathways.

Massive gasification facilities have the greatest technical potential for biomethane with CCS, especially in areas with existing infrastructure for biomass transport, natural gas distribution, and CO₂ sequestration. Small-scale biomethane production with CCS based on anaerobic digestion may be restricted to specific applications due to the economies of scale associated with carbon capture equipment. However, smaller facilities that share carbon capture infrastructure may be able to overcome these limitations.

Evaluating the Pros and Cons of Implementing Carbon Capture

While incorporating carbon capture into biomethane production does increase capital and operating expenses, the positive impact on the environment can make this investment worthwhile, especially in areas with supportive policies. Research shows that carbon capture typically adds between €10-30 per MWh to the cost of biomethane production, which represents a cost increase of approximately 15-25%. Despite this, the improved environmental performance makes up for the increased cost, as emissions reductions typically increase by 50-150% compared to standard biomethane production.

As carbon pricing mechanisms begin to appreciate these enhanced climate benefits, the economics become more and more favourable. Analysis suggests that carbon prices of €50-70 per tonne CO₂ could make biomethane with CCS economically competitive with conventional biomethane in many situations. As carbon prices rise to meet climate ambitions, the economic argument for integrated carbon capture will become even stronger.

Examples of Current Large-Scale Implementation

Even though the technology is still developing, there are several pioneering projects that are showing the viability of biomethane with carbon capture at commercial scales. The DRAX power station in the UK is developing a BECCS system that will capture biogenic CO₂ from biomass gasification, potentially removing up to 16 million tonnes of CO₂ annually when fully operational. In Denmark, the Avedøre Wastewater Treatment Plant captures CO₂ from its biogas upgrading process for use in greenhouse plant growth, demonstrating how biogenic carbon can be recirculated in productive agricultural systems.

The Illinois Industrial Carbon Capture and Storage project, though it primarily deals with ethanol rather than biomethane production, shows that large-scale biogenic carbon capture and geological storage is technically possible, sequestering over 1 million tonnes of biogenic CO₂ every year. These trailblazing projects are setting the technical groundwork and operational experience that will facilitate broader implementation of integrated biomethane and carbon capture systems.

Financial Feasibility of Low-Carbon Biomethane

The shift towards biomethane as a low-carbon energy alternative is ultimately contingent on its financial feasibility. While the environmental benefits are significant, broad adoption necessitates competitive production costs, favourable carbon pricing, and efficient incentive structures.

Comparing the Production Costs of Biomethane and Fossil Gas

At present, the typical production costs for biomethane range from €50-90 per MWh. In contrast, conventional natural gas costs €20-30 per MWh to produce. However, the recent volatility in the energy market has significantly reduced this cost difference. The cost differential is subject to the type of feedstock, the scale of the facility, and the conditions of the local market. Biomethane production based on waste generally has lower costs than pathways dedicated to energy crops. This is especially true when there are available waste disposal credits or tipping fees. Larger facilities can take advantage of economies of scale. As a result, the production costs for industrial-scale operations are typically 15-25% lower than those of small farm-based systems.

How Carbon Pricing Affects Competitiveness

By putting a price on carbon emissions, biomethane's climate benefits become a financial asset. Whether it's carbon taxes, emissions trading systems, or other market mechanisms, if carbon emissions cost money, biomethane becomes a much more economically competitive option. Studies suggest that carbon prices around €70-100 per tonne CO₂e can make biomethane just as cost-effective as natural gas that hasn't been reduced or eliminated in many European situations, without needing any extra subsidies.

When taking into account the full carbon benefit of waste-based biomethane pathways that prevent methane emissions from traditional waste management, the economic equation becomes even more favourable. When properly accounting for both direct and avoided emissions, these projects can remain economically viable at lower carbon prices of €30-50 per tonne CO₂e. Discover how LFG-to-energy conversion units are transforming landfill gas in California.

Government Incentives Encouraging Adoption

Governmental policies around the world are establishing supportive frameworks for biomethane production through different incentive structures. Feed-in tariffs, renewable gas quotas, and tax incentives have been particularly successful in stimulating market growth. The Renewable Energy Directive of the EU sets binding targets for renewable energy in transport and heating, creating demand for biomethane in various sectors. In North America, Low Carbon Fuel Standards in California and Oregon have created premium markets for biomethane as a transport fuel, where credit values sometimes exceed the base commodity value of the gas itself.

Embrace Biomethane for a Sustainable Energy Future

Transitioning to sustainable energy systems demands solutions that provide significant climate advantages while ensuring energy security and affordability. Biomethane emerges as a flexible, scalable technology capable of tackling various facets of this energy transition, from waste management to renewable gas production and carbon elimination. By comprehending the carbon footprint implications of diverse production routes, stakeholders can make knowledgeable decisions that optimise both environmental and economic gains.

Are you interested in discovering how biomethane can help lower your company's carbon emissions while also providing a dependable source of renewable energy? CleanTech Bioenergy Solutions provides a wide range of consulting services to help you find the best biomethane solution for your unique requirements, whether you're handling organic waste, looking for a source of renewable gas, or developing strategies for carbon-negative energy.

Common Questions

Many people have questions about biomethane and its role in sustainable energy systems. They wonder about its environmental impact, how it's produced, and how it can be used. Here are answers to some of the most frequently asked questions:

Understanding Biomethane and Its Differences from Natural Gas

Biomethane is a renewable form of natural gas that is produced from organic materials using anaerobic digestion or gasification processes. While it is chemically identical to traditional natural gas (primarily methane, CH₄), biomethane can be used as a direct replacement for fossil gas in a variety of applications, including heating, cooking, electricity generation, and vehicle fuel. The key difference between the two is in the carbon cycle: natural gas releases carbon that has been stored underground for millions of years, resulting in a net increase in atmospheric CO₂, while biomethane simply returns carbon to the atmosphere that was recently captured by organic materials, creating a closed carbon loop.

It's important to understand that the environmental impact of biomethane can be either carbon-neutral or carbon-negative, depending on the production methods used. This is a stark contrast to fossil natural gas, which always results in a rise in atmospheric carbon levels. Furthermore, biomethane production often involves the capture of methane from waste streams that would otherwise contribute to greenhouse gas emissions, offering an additional climate advantage beyond the direct replacement of fossil fuels.

Is it possible for biomethane to be carbon negative? Can you explain how this is possible?

Yes, it is possible for biomethane production to be carbon negative through several processes. The most direct way to achieve negative emissions is by combining carbon capture and storage (CCS) with biomethane production. During the process of upgrading biogas, CO₂ is separated from methane. This CO₂ is biogenic, which means that it was recently captured from the atmosphere by plants through photosynthesis. When this CO₂ is captured and permanently stored instead of being released back into the atmosphere, it results in a net removal of carbon from the atmospheric cycle.

Another way to reduce carbon intensity is to produce biomethane from waste streams that have a high potential for methane production, like livestock manure. These projects can achieve significant emissions reductions beyond the direct displacement of fossil fuels by capturing methane that would otherwise be released during waste decomposition (methane has 28 times the global warming potential of CO2). When you combine these avoided methane emissions with the benefit of displacing fossil fuels, the net carbon impact can be strongly negative, even without dedicated carbon capture systems.

What kinds of organic waste can be converted into biomethane?

Almost any kind of organic material can be transformed into biomethane using the right conversion technologies. The best feedstocks for anaerobic digestion are high-moisture, easily degradable materials like food waste, agricultural residues, manure, sewage sludge, and some industrial organic byproducts. These materials break down relatively quickly in oxygen-free environments, producing biogas that can be upgraded to biomethane.

Gasification technologies allow us to use a wider range of feedstocks, including woody, lignocellulosic materials such as forestry residues, wood waste, and high-fibre agricultural byproducts that aren't as suitable for conventional anaerobic digestion. This thermochemical method turns these materials into syngas, which we can then turn into biomethane through methanation processes.

By focusing on waste streams and residues rather than dedicated energy crops, the most sustainable and carbon-effective methods avoid potential land-use conflicts and maximise climate benefits through integrated waste management and energy production. The perfect feedstock mix varies by region, depending on local agricultural activities, waste management systems, and industrial operations.

- Manure and waste from dairy cows, pigs, and chickens

- Food waste from homes, restaurants, and food processing

- Agricultural leftovers like corn stalks, rice straw, and fruit/vegetable scraps

- Sewage sludge from wastewater treatment plants

- Industrial organic leftovers from breweries, distilleries, and food manufacturing

- Landfill gas captured from existing waste disposal sites

- Forest leftovers and wood processing scraps (via gasification)

How much does it cost to make biomethane compared to fossil fuels?

Right now, it costs about €50-90 per MWh (or $15-25 per MMBtu) to make biomethane, while natural gas usually costs about €20-30 per MWh ($5-8 per MMBtu) under normal market conditions. But this price difference has gotten a lot smaller recently because of changes in the energy market. Sometimes, natural gas has even cost more than biomethane in some parts of Europe during 2022-2023. The cost can change a lot depending on how much the feedstock costs, how big the facility is, and what the local market conditions are.

Producing biomethane is fundamentally different in cost from fossil gas. Natural gas costs are dominated by fuel prices and have relatively low capital intensity, whereas biomethane has higher capital investment but minimal fuel costs when using waste streams. In many cases, biomethane producers actually get tipping fees or waste disposal credits for their feedstocks, which improves the economics.

Additionally, as carbon pricing mechanisms mature and more fully account for the climate impacts of different energy sources, the economic competitiveness of biomethane will continue to improve relative to fossil alternatives.

What government actions would speed up the global acceptance of biomethane?

Effective policy frameworks for accelerating biomethane adoption typically combine market-based mechanisms with targeted regulatory support. Carbon pricing—whether through carbon taxes, emissions trading systems, or other approaches—provides the foundation by monetising biomethane's climate benefits. Specific renewable gas targets or quotas create demand certainty that supports investment, particularly when coupled with guarantees of origin systems that verify the renewable attributes of the gas.

One way to address the high upfront costs of biomethane projects is through tax incentives, such as accelerated depreciation allowances. In North America, low-carbon fuel standards that account for the complete life-cycle emissions benefits of biomethane in transport have been very effective. Support for grid connection, including preferential interconnection terms and cost-sharing mechanisms for biomethane injection infrastructure, can help smaller producers overcome a major barrier to market entry.

Most importantly, policies that take a holistic approach—acknowledging biomethane's contributions to waste management, renewable energy, agriculture, and climate mitigation—tend to provide the most effective support. By creating incentives across these sectors, policymakers can fully harness the power of biomethane as a multifaceted solution to numerous sustainability issues.

EC Support for Biomethane Fuel Grows – Doubling Production by 2030 Considered for France

The news is that EC support for biomethane fuel is continuing apace. So much so that a doubling of biomethane production by 2030 is being considered by the authorities in France. To us this makes sense. It is a sustainable and environmentally friendly option for energy production and is considered a key component in the […]